Optimizing Performance and Durability in Sports Equipment Manufacturing

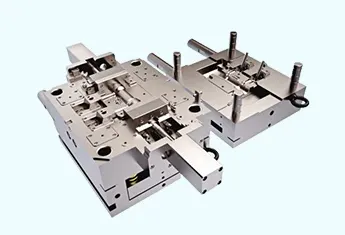

Sports Plastic Mold

Sports plastic molds are specialized tooling solutions used to manufacture high-performance plastic components for sports and fitness equipment. These molds support the rapid and consistent production of complex parts with excellent dimensional stability and durability. From protective gear to equipment casings, the plastic injection molding process enables mass production with minimal material waste and high design precision.

-

Material Versatility

-

Precision Manufacturing

-

International Mold Standards

Sample Display of Sports Plastic Mold

Sports plastic molds are used to create high-quality, functional prototypes and mass-produced components for various sports equipment. These molds ensure precise replication of designs, meeting the specific requirements of each product, from aesthetics to durability.

Applications of Sports Plastic Mold

Sports plastic molds are essential in producing durable and high-performance components for various sports equipment. They are used to create items such as helmets, cleats, training tools, and protective gear, ensuring precision and reliability.

-

Protective Gear Shells

-

Fitness Equipment Components

-

Water Sports Equipment

-

Cycling Accessories

-

Winter Sports Equipment

-

Racquet Sports Gear

Why Sports Plastic Molds Enhance Equipment Durability

Sports plastic molds are critical in the production of high-quality, durable sports equipment. These molds ensure precise and consistent manufacturing of components used in various sports gear, from protective equipment to accessories. With advancements in plastic molding technologies, sports plastic molds have become an essential tool for creating products that can withstand rigorous conditions and frequent use.

High Durability

Ensures that sports equipment can endure high-stress conditions over long periods, improving its lifespan and reliability.

Customization

Allows for tailored designs to meet specific needs of athletes or sports applications, ensuring optimal performance.

Efficiency

Facilitates high-volume production with consistent quality, reducing lead times and production costs while maintaining standards.

Material Versatility

Supports the use of various plastics, offering flexibility to create different types of sports gear with unique properties.

Cost-Effective

Optimizes manufacturing processes, reducing material waste and energy consumption, thus lowering overall production costs.