Ingenious Mold Structure

The product is actually very simple. An antenna is covered with a layer of soft glue. The most important thing in making this type of mold is how to fix the co-plastic parts inside. Due to the limitation of product structure, this product is formed on a vertical machine, and the antenna is placed into the mold by hand. How to place the antenna to ensure that it will not loosen, the simple way is to press it with something. Press it with what?

There is a concept, when the co-plastic parts are put in, manually advance the row position to press the co-plastic parts, so the problem arises. When the mold is closed, the inclined guide column interferes with the row position. How to open the slider when the mold is opened?

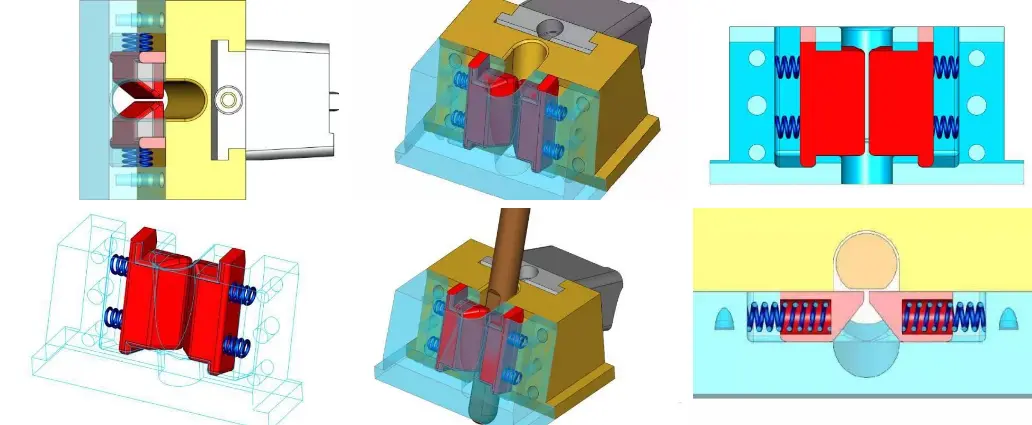

In order that the inclined guide post will not interfere with the row position when the mold is closed again, and the inclined guide post can pull the row position apart when the mold is opened, the designer made a small opening and closing mechanism on the inclined guide post and the row position. When the mold is opened, it is buckled, and there is no interference when the mold is closed (as shown in the figure below)

It can be seen from the picture that there is a set of buckle machines added to the row seat. When the mold is opened, the inclined guide column touches the inner plane of the buckle machine to pull the slider apart. When the mold is closed, the inclined guide column is inserted into the outer slope of the buckle machine. , forcing the locking machine to open to both sides, and allowing the inclined guide column to enter the road. After the inclined guide column is fully entered, the locking machine resets under the action of the spring and buckles the inclined guide column.