Customized Injection Moulds for Beauty and Skincare Devices

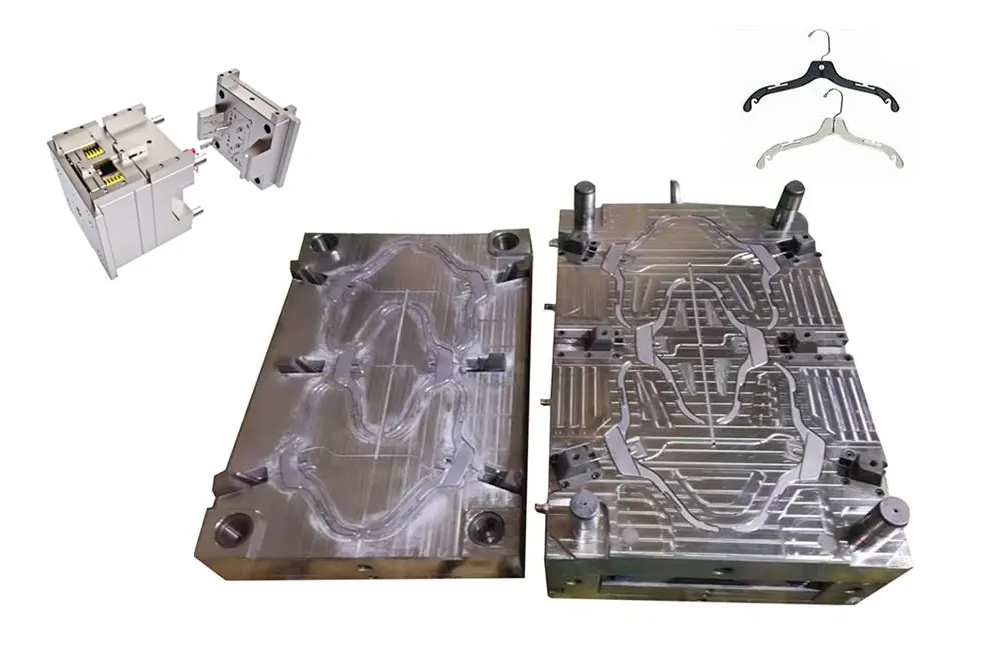

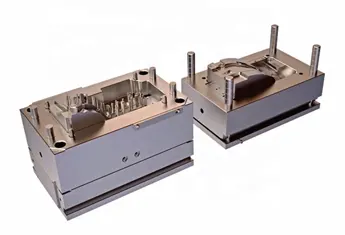

Beauty and Health Care Mould

Beauty and health care moulds are designed for manufacturing precision plastic parts used in beauty devices like facial steamers, sterilizers, massagers, and cleansing tools. With advanced injection techniques, these moulds ensure safety, functionality, and aesthetic appeal.

-

Material Versatility

-

Precision Manufacturing

-

International Mold Standards

Durable Moulds for Health Tools

We offer expertly crafted moulded parts for various beauty and health care devices, including insert molding, silicone molding, and high-gloss housings. These samples demonstrate our diverse capabilities in structure, surface treatment, and complex assembly integration.

Application Fields

Our mould solutions serve a wide range of beauty and health-related consumer products, offering high-precision components for personal care, wellness, sterilization, and baby care sectors.

-

Personal Beauty Devices

-

Health and Wellness Equipment

-

Mother and Baby Products

-

Home-use Sterilization Tools

-

Smart Skincare Devices

-

Aesthetic Therapy Tools

Why Choose Beauty and Health Care Moulds?

Our Beauty and Health Care Moulds are designed for high-precision, high-aesthetic applications such as facial devices, sterilizers, and wellness tools. With deep industry experience and multi-process integration capabilities, we help brands accelerate product development with reliable, cosmetic-grade mould solutions.

Expertise in Beauty

With years of experience in designing and developing moulds for beauty devices, we have worked on numerous successful projects involving cleansing brushes, beauty instruments, and massagers.

Functional Integration

Our moulds can be customized to support a variety of functions, such as current import/export and packaging of beauty treatment modules, addressing the unique needs of diverse products.

Multi-process Support

We offer seamless integration of different manufacturing processes like 2K injection, insert moulding, and silicone overmoulding, facilitating the rapid creation of innovative products.

Tight Tolerance Fit

Our moulds are engineered to meet high precision requirements, ensuring a flawless fit and smooth assembly, even for the most complex beauty equipment.

Long-lasting Durability

By selecting premium materials and optimizing heat treatment processes, our moulds are built for durability, ensuring extended service life even during long production runs.