Plastic Injection Mould

Plastic molds are indispensable in modern plastic manufacturing, allowing for the efficient mass production of highly detailed and dimensionally accurate components. Constructed from robust materials such as steel or aluminum, these molds are central to processes like injection molding, blow molding, and thermoforming, delivering consistent quality, high precision, and excellent repeatability across a wide range of applications.

- T1 sample as fast as 1-2 weeks

- No minimums

- ISO 9001:2015, ISO14001:2015, IATF 16949:2016 certified

- Overview

- Production Capability

- Materials

- Finishes

- Why Choose Us

- Resources

Expertise in High-Performance Molding

From Design to Production

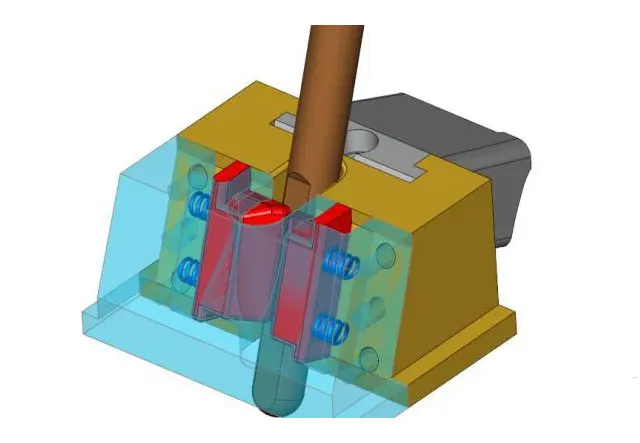

Plastic injection molding is a precise and efficient method of producing high-quality plastic parts. It covers design review, mold making, testing, and final production, ensuring accuracy and consistency through every step.

Reliable Plastic Injection Molding Solutions

We provide end-to-end injection molding services, from DFM review to mold fabrication and mass production. Using advanced analysis and precision tooling, we deliver consistent, high-quality plastic parts designed to meet your specific requirements.

Materials for Manufacturing

We offer a range of materials, including plastics, metals, and composites, selected for their strength, durability, and resistance to heat and chemicals. These materials ensure high-quality, long-lasting products for industries like automotive, electronics, and medical.

We can source any other materials upon request! If you don’t see the material you need please contact us

Some of Our Samples

These samples highlight our expertise, but we provide a wide range of additional services.

Why Choose Us?

SunOn Industrial Group Limited offers end-to-end services from product design to mass production, specializing in high-quality solutions for industries like home appliances, automotive, and medical devices. With over 25 years of experience and a global presence, we ensure reliable, cost-effective solutions and seamless service from prototype to final assembly.

- One-stop solutions from prototype to packaging.

- Timely support across 27 cities worldwide.

- Experienced engineers ensuring quality results.

- ISO 9001, IATF 16949, ISO 14001 certified.

Industry Application

We produce millions of parts for diverse industries, including automotive, medical, robotics, automation, communications, consumer electronics, and LED lighting, delivering top-quality products.

FAQs

When can I get the price?

Could you provide a sample for us?

What is your MOQ for the products?

What service you can provide?

When did you start to export moulds to USA and Europe?

What is your main product?

Manufacturing Resources

Start production of your parts today