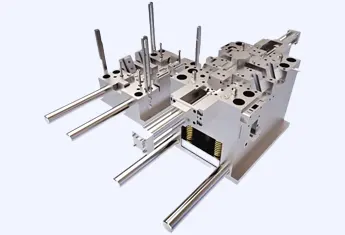

Tailored mould solutions for efficient home appliance production

Home Appliance Mould

We specialize in designing and manufacturing high-precision injection moulds for home appliances, covering products like TV shells, washing machine panels, air conditioner housings, and refrigerator components. Our service ensures optimized part structure, consistent product quality, and faster production cycles.

-

Material Versatility

-

Precision Manufacturing

-

International Mold Standards

Efficiency in Moulding

Below are images showcasing our high-precision home appliance moulds that demonstrate our craftsmanship and the quality of the finished products we help create.

Home Applications

Our custom home appliance moulds are widely used in producing plastic enclosures, panels, and internal components for appliances such as refrigerators, washing machines, air conditioners, and kitchen tools. They help ensure consistent part quality, seamless fitment, and efficient assembly across various product lines.

-

TV rear covers

-

Washing machine panels

-

Air conditioner control shells

-

Refrigerator drawers & bins

-

Blender & juicer shells

Why It Fits the Home Appliance Industry

Our mould service is tailored to meet the high-volume, high-precision, and aesthetic demands of modern home appliance manufacturing. With deep expertise in large-size part forming and surface finish control, we ensure stable production of durable, visually appealing components that meet strict consumer standards.

Precise Making

Our moulds are built with high precision to meet the demanding standards of home appliance products, ensuring high-quality and functional components.

Durable Materials

We use high-grade materials like S136, P20, and NAK80 to guarantee longevity and reliability for long-term production cycles.

Efficiency Boost

SunOn’s moulds feature advanced designs that improve production efficiency, reduce waste, and lower costs in high-volume manufacturing.

Custom Solutions

Tailored moulds for various appliance types ensure compatibility and efficiency, tailored to your specific product needs.

Surface Innovation

Our moulds are polished to a high-gloss finish, providing aesthetic appeal and smoother product release.