Precision Solutions for Business Equipment

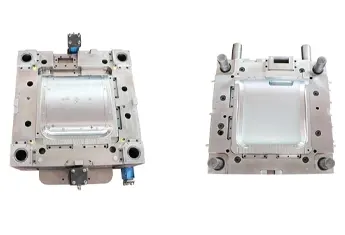

Office Mould

Our office moulds are tailored to produce high-precision, lightweight, and stylish plastic enclosures for POS systems, printers, and other office devices. With excellent dimensional stability and design flexibility, they ensure both functionality and aesthetics for commercial-grade products.

-

Material Versatility

-

Precision Manufacturing

-

International Mold Standards

Office Equipment Mold Examples

We specialize in crafting high-precision molds tailored for a wide range of office electronics. These examples showcase the versatility, dimensional stability, and surface excellence of our injection-molded components. From compact POS terminals to large multifunction printers, our molds are designed to meet the rigorous demands of the modern office environment.

Office Applications

Our office equipment molds are widely applied in the production of precision housings and internal components for modern business devices. These molds ensure structural strength, aesthetic surface quality, and tight assembly tolerance, meeting the high-performance requirements of various office environments. Whether for compact desk tools or large multifunction systems, our mold solutions guarantee durability, stability, and reliable mass production.

-

POS Systems

-

Printers

-

Cash Registers

-

Desktop Document Scanners

-

Shredder Housing

-

Teleconferencing Equipment

Why It Fits the Office Equipment Industry

High Dimensional Accuracy

Ideal for thin-walled and complex parts, ensuring stable fit and smooth assembly for precision office electronics.

Lightweight and Durable

Combines the light weight of plastics with superior impact resistance, offering better portability and structural strength.

Enhanced Appearance Quality

Molds produce rich surface textures and smooth finishes that improve grip and reflect premium design.

Excellent Processing Flowability

Materials like PC+ABS offer easy molding, reduced defects, and suitability for mass production.

Cost-Efficient Production

Optimized mold design allows consistent quality at lower cost, fitting large-scale manufacturing requirements.